Industrial dust collection systems are essential components in today's manufacturing landscape, playing a critical role in maintaining clean and safe work environments. As industries evolve, so does the need for effective solutions that mitigate airborne particulates and ensure compliance with health and safety regulations. These systems not only protect workers from harmful dust exposure but also contribute significantly to the overall sustainability efforts of organisations. By implementing efficient dust collection methods, manufacturers can optimise their workflows while reducing their environmental footprint.

Incorporating these systems into manufacturing processes is not just about meeting compliance standards; it’s about fostering a culture of safety and sustainability. The adverse effects of dust on both human health and machinery can be profound, leading to decreased productivity and increased health risks for employees. As the industry faces growing concerns over environmental impact and worker safety, investing in innovative dust collection technologies becomes a vital strategy for responsible manufacturing. This blog will explore the various benefits of industrial dust collection systems, highlighting their importance in promoting not only cleaner air but also a more sustainable future for all.

Industrial dust collection systems play a pivotal role in maintaining a safe and efficient manufacturing environment. At their core, these systems are designed to capture and filter airborne particulate matter produced during manufacturing processes. Dust can arise from various sources, including machining, sanding, grinding, and other operations that generate fine particles. Without effective dust control measures, these particulates can pose serious health risks to workers and lead to equipment malfunctions, decreased productivity, and compromised product quality.

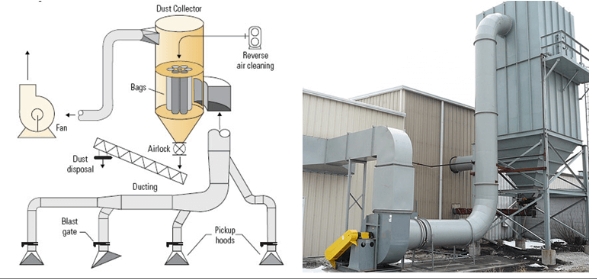

The primary components of dust collection systems include dust collectors, ductwork, air cleaners, and hoods. These systems work by drawing in contaminated air and passing it through filters that trap dust particles, allowing clean air to be recirculated back into the workspace. There are several types of dust collectors, such as baghouses, cartridge collectors, and cyclone separators, each designed to address specific dust types and volumes. Choosing the right system depends on factors like the nature of the dust, the size of the facility, and regulatory requirements.

Implementing an industrial dust collection system is not merely a compliance issue; it is an investment in the health of your workforce and the efficiency of your operations. By reducing airborne pollutants, these systems help mitigate respiratory illnesses, improve worker morale, and minimise the potential for accidents caused by slip hazards or equipment failures. Furthermore, maintaining a clean work environment can enhance equipment longevity and decrease maintenance costs, ultimately leading to significant savings.

In the context of sustainable manufacturing, industrial dust collection systems contribute to lower emissions and waste reduction, aligning with corporate environmental goals. As global regulations around air quality become more stringent, companies that prioritise effective dust management will not only comply with these regulations but also enhance their reputation as socially responsible organisations.

To ensure optimal performance, regular maintenance and evaluation of dust collection systems are essential. Monitoring airflow, filtering efficiency, and system integrity will help identify potential issues before they escalate into costly problems. Additionally, educating employees on the importance of dust management and the function of these systems fosters a culture of safety and responsibility within the workplace.

In the fast-paced world of manufacturing, efficiency and productivity often take the front seat. However, the issue of industrial dust can pose significant health risks that should not be overlooked. Exposure to airborne particulates is a common yet often underestimated hazard in manufacturing environments. Understanding the health risks associated with these dust particles is crucial for both workforce safety and operational sustainability.

Industrial dust can originate from various processes, including cutting, grinding, welding, and sanding. The nature of the dust depends on the materials involved, which can range from wood and metals to chemicals and plastics. Common types of industrial dust include:

•Wood Dust:Generated during woodworking processes, exposure can lead to respiratory issues and allergic reactions.

•Metal Dust:Produced from machining operations, metal dust can contain toxic heavy metals that pose serious health risks.

•Silica Dust:Common in construction and mining, crystalline silica is a known carcinogen that can lead to silicosis, a chronic lung disease.

•Chemical Dust:Substances like powders from pigments or other additives can cause respiratory irritation and other health complications.

One of the most serious health concerns related to dust exposure is the development of respiratory problems. Inhalation of dust particles can lead to various conditions, including:

•Asthma:Dust exposure can exacerbate asthma symptoms or trigger new onset asthma in sensitive individuals.

•Chronic Obstructive Pulmonary Disease (COPD):Long-term inhalation of particulates can lead to chronic bronchitis and emphysema, resulting in diminished lung function.

•Lung Cancer:Prolonged exposure to certain types of dust, especially silica and asbestos, significantly increases the risk of developing lung cancer.

Many workers can develop allergies or skin conditions due to dust exposure. Wood dust, for example, may cause allergic skin reactions, while other types of dust can exacerbate existing skin conditions. Implementing proper dust control measures can help mitigate these risks and create a more comfortable working environment.

Emerging research suggests that certain types of industrial dust, particularly those containing heavy metals, can lead to neurological issues over time. Symptoms may include cognitive decline, mood changes, and other neurological disorders, making it essential for industries to understand and address the long-term effects of dust exposure.

The mental well-being of employees can also be affected by working in a dusty environment. Concerns over health risks can lead to increased stress and anxiety levels, which can adversely affect morale and productivity. Creating a healthier workplace can improve not just physical health but also mental health, leading to a more cohesive and engaged workforce.

Given the multitude of health risks associated with industrial dust, effective dust management is essential. Companies should invest in high-quality dust collection systems, implement routine maintenance, and foster a culture of safety that prioritises employee health. Regular training for employees on the importance of dust management and the potential risks associated with dust exposure is paramount.

The health risks of dust in manufacturing environments are significant and multifaceted. By understanding these dangers and taking proactive steps to manage exposure, manufacturers can protect their workforce, enhance overall safety, and contribute to a sustainable operational model. Prioritising dust control not only safeguards employees but also supports a company's bottom line and reputation in an increasingly health-conscious market.

How Dust Collection Systems Enhance Workplace Safety

In manufacturing and industrial environments, maintaining a safe workplace is paramount. One of the most effective measures for enhancing safety is the implementation of dust collection systems. These systems are specifically designed to capture and filter harmful airborne particles, significantly reducing the risk of health hazards and accidents. In this article, we explore how dust collection systems contribute to a safer work environment, ultimately protecting both employees and the organisation.